2013 March 19: Install the left cylinder head

Created:

Updated:

First entry|Previous entry|Next entry|Last entry

Continuing with the left side, here is the head gasket in place. Note oil return hole is properly aligned.

Continuing with the left side, here is the head gasket in place. Note oil return hole is properly aligned.Photo courtesy of Gregory Bender.

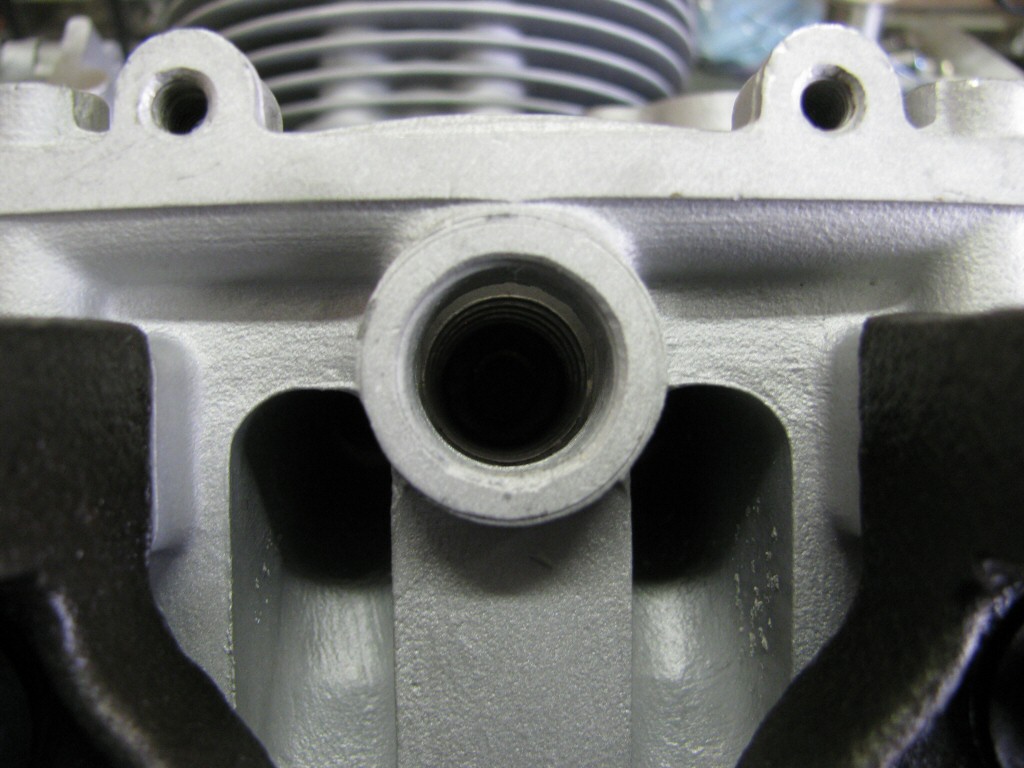

The reconditioned cylinder head: new exhaust valve, re-used intake valve, new valve guides.

The reconditioned cylinder head: new exhaust valve, re-used intake valve, new valve guides.Photo courtesy of Gregory Bender.

Cylinder head in place.

Cylinder head in place.Photo courtesy of Gregory Bender.

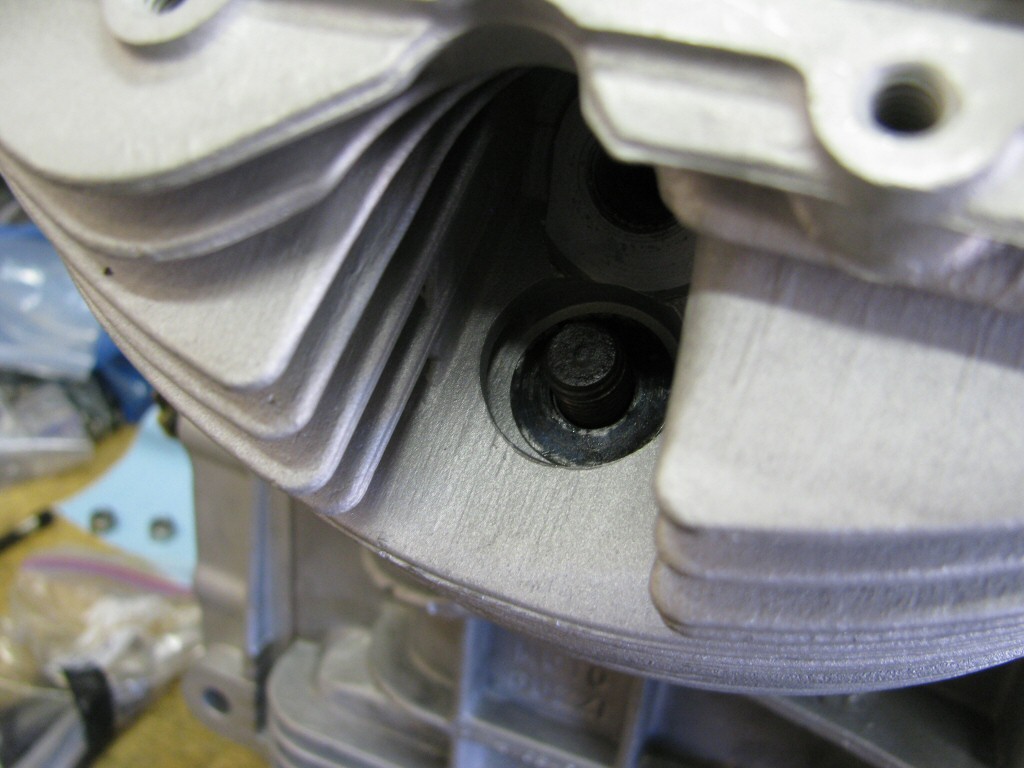

O-rings fit to the four protruding studs.

O-rings fit to the four protruding studs.Photo courtesy of Gregory Bender.

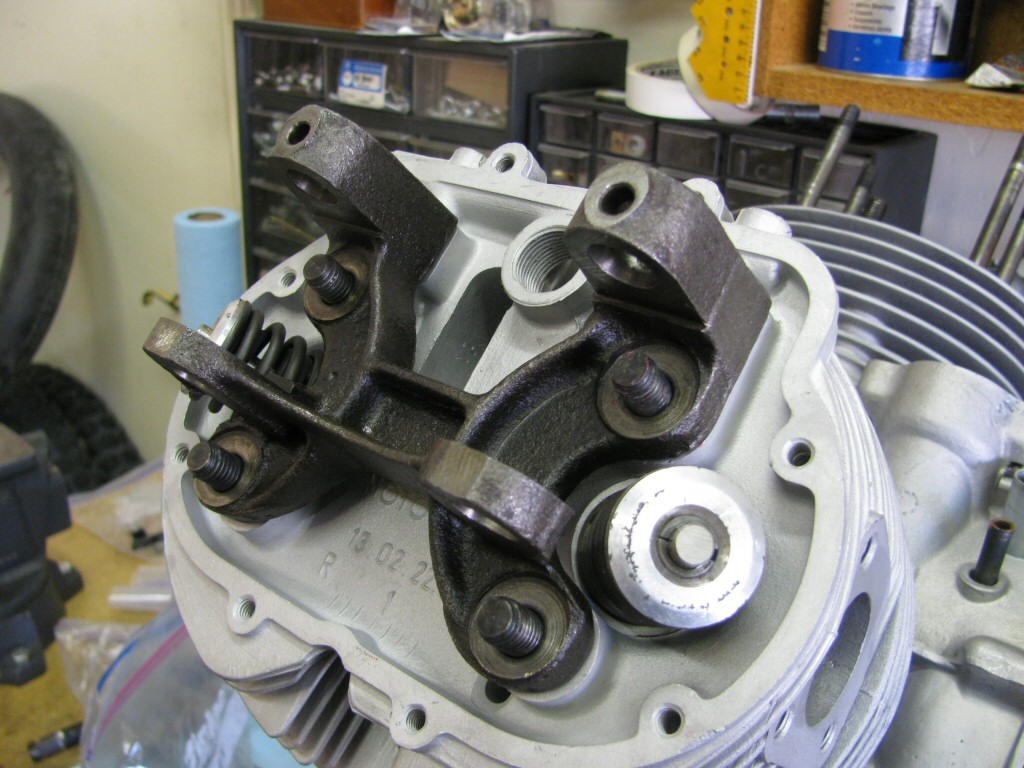

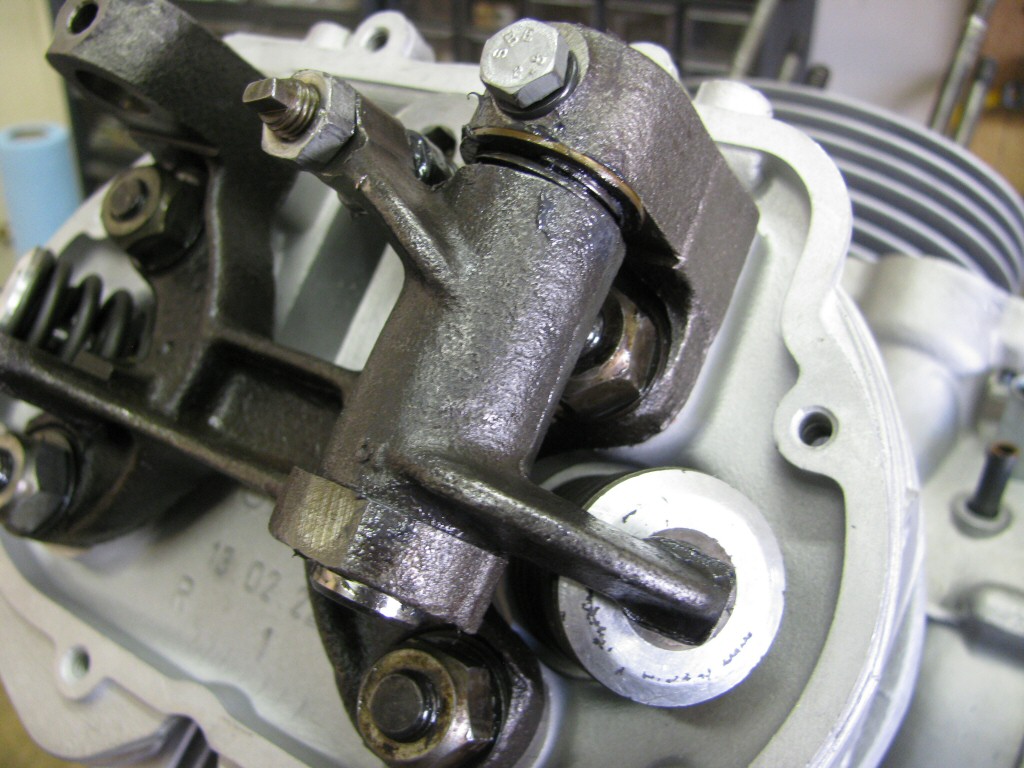

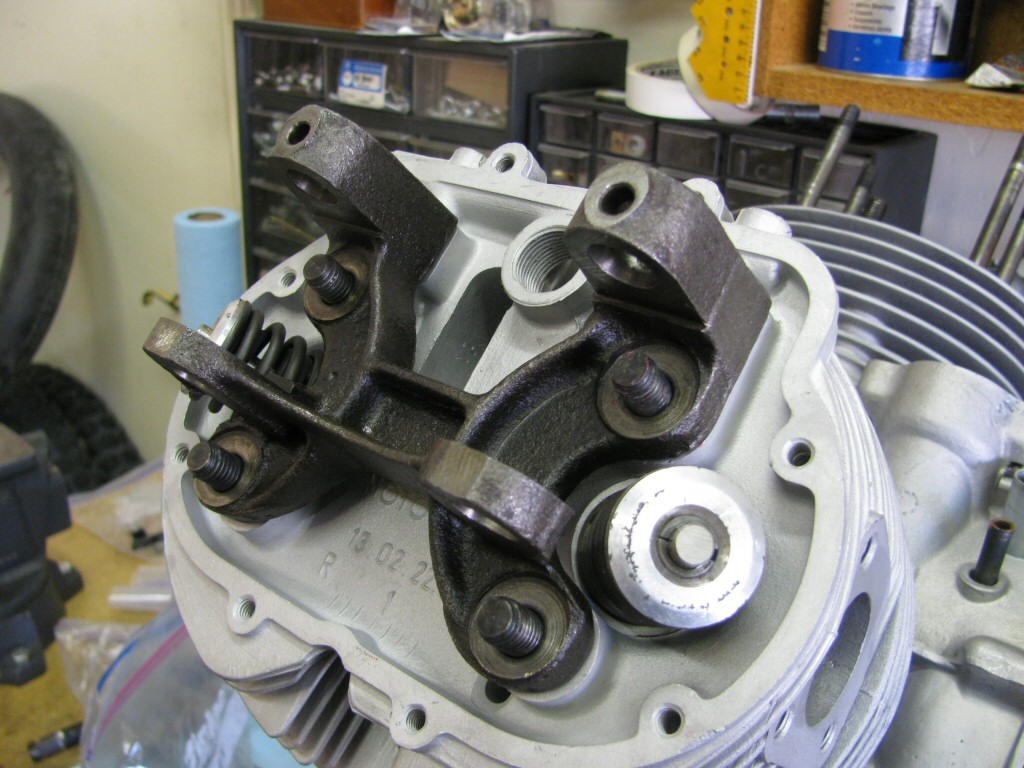

Rocker arm tressle fit.

Rocker arm tressle fit.Photo courtesy of Gregory Bender.

Flat washers fit above the tressle.

Flat washers fit above the tressle.Photo courtesy of Gregory Bender.

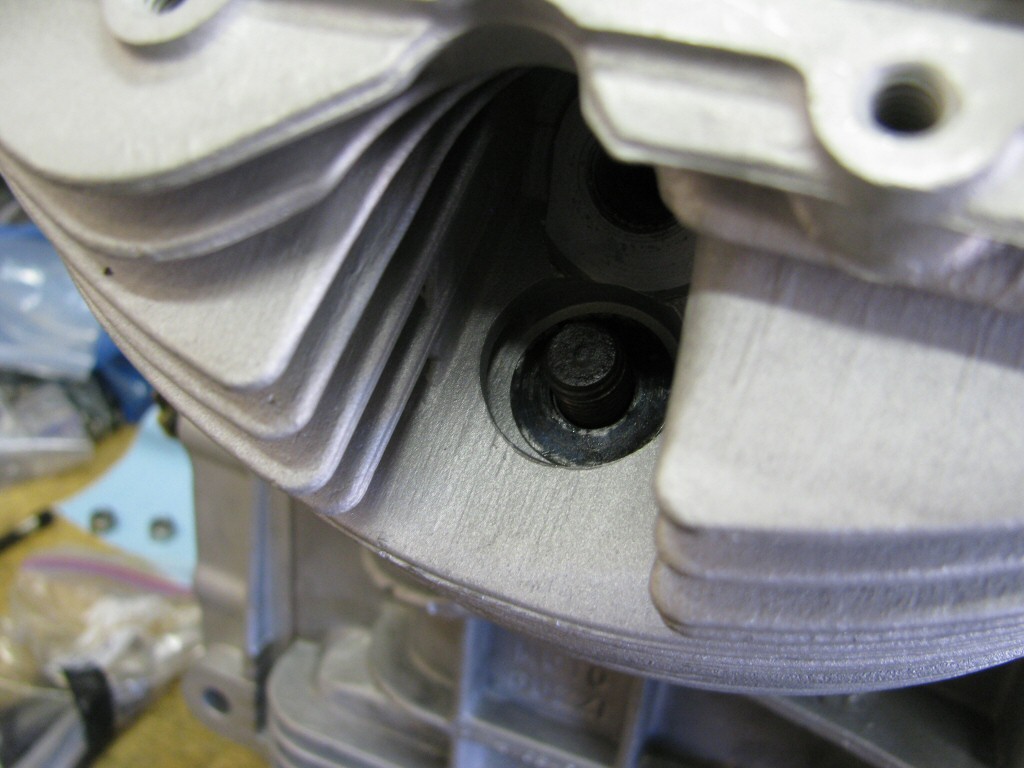

Flat washer fit to the

Flat washer fit to the 6 o'clock

stud.Photo courtesy of Gregory Bender.

You can't see it, but a flat washer is fit to the

You can't see it, but a flat washer is fit to the 12 o'clock

stud.Photo courtesy of Gregory Bender.

Four nuts on the tressle studs.

Four nuts on the tressle studs.Photo courtesy of Gregory Bender.

Because they are exposed to the elements, I apply antiseize to the threads of the

Because they are exposed to the elements, I apply antiseize to the threads of the 12 o'clock

and 6 o'clock

nuts.Photo courtesy of Gregory Bender.

Then the nuts get torqued to spec.

Then the nuts get torqued to spec.Photo courtesy of Gregory Bender.

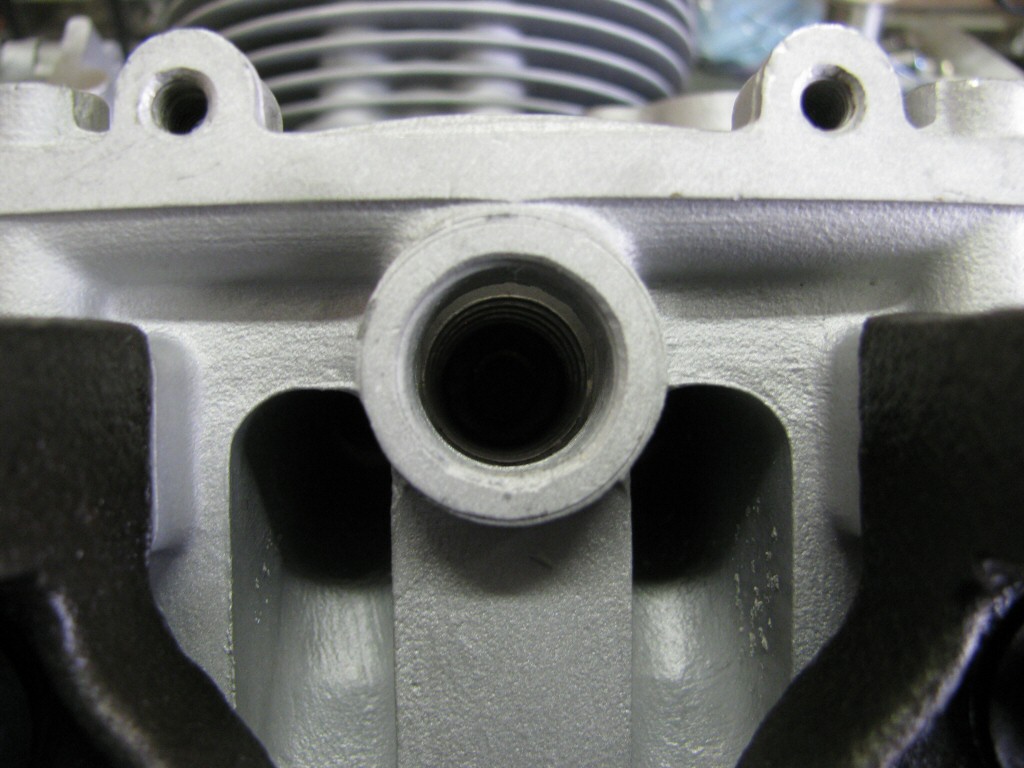

I fit a new O-ring to the plug for the

I fit a new O-ring to the plug for the 12 o'clock

nut access hole.Photo courtesy of Gregory Bender.

Again, I apply anti-seize to the threads.

Again, I apply anti-seize to the threads.Photo courtesy of Gregory Bender.

The plug tightened in place.

The plug tightened in place.Photo courtesy of Gregory Bender.

Here are the parts needed to actuate the intake valve.

Here are the parts needed to actuate the intake valve.Photo courtesy of Gregory Bender.

Everything gets a good coating of assembly lube.

Everything gets a good coating of assembly lube.Photo courtesy of Gregory Bender.

The intake valve components in place.

The intake valve components in place.Photo courtesy of Gregory Bender.

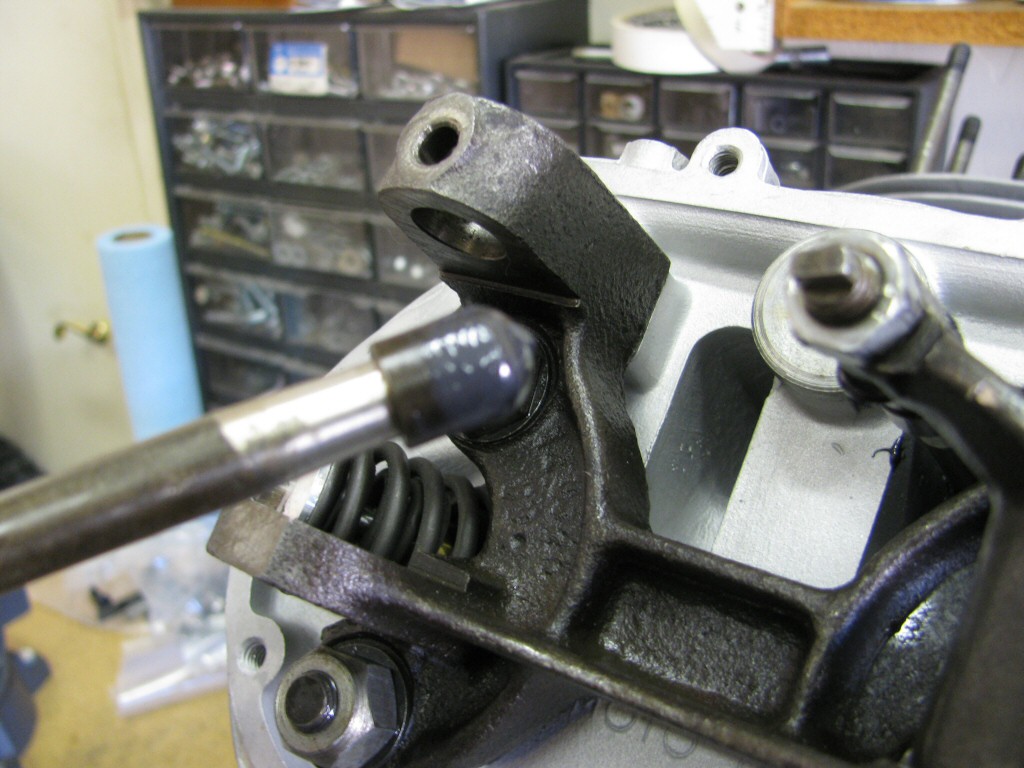

Here are the parts needed to actuate the exhaust valve.

Here are the parts needed to actuate the exhaust valve.Photo courtesy of Gregory Bender.

Everything gets a good coating of assembly lube.

Everything gets a good coating of assembly lube.Photo courtesy of Gregory Bender.

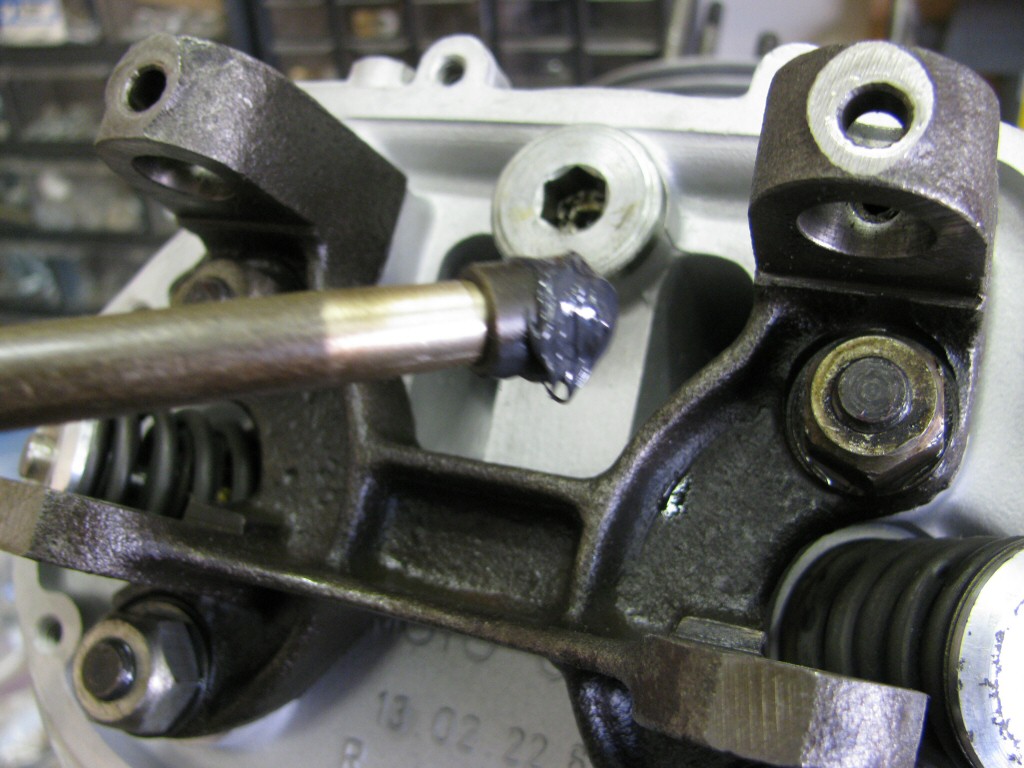

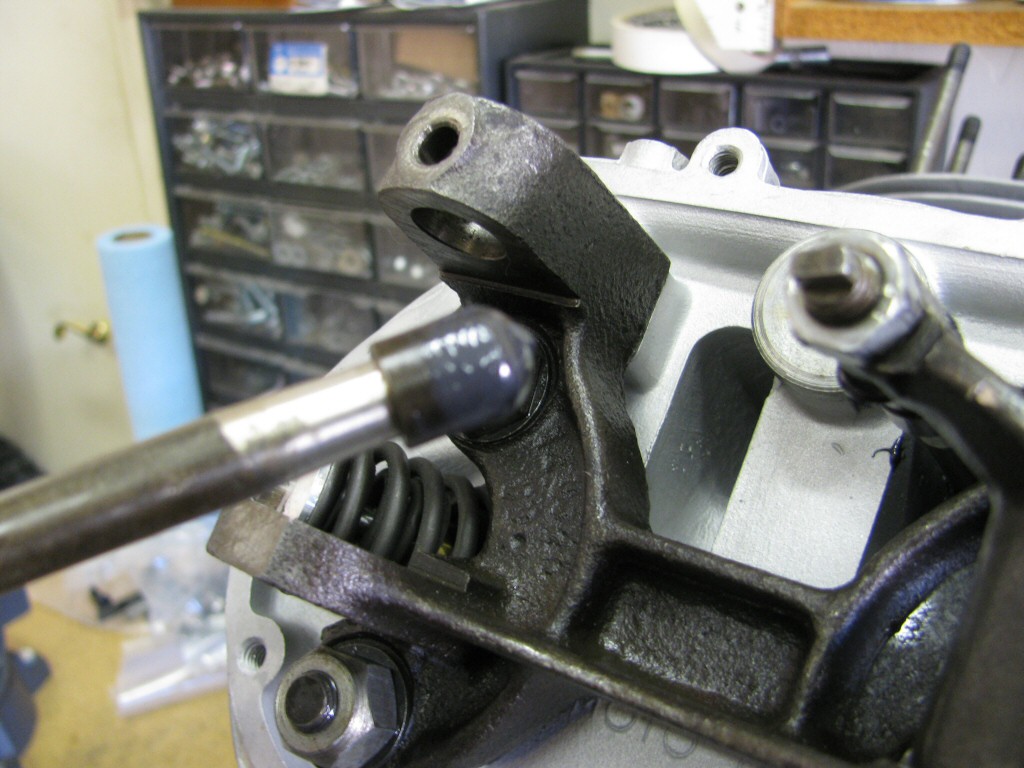

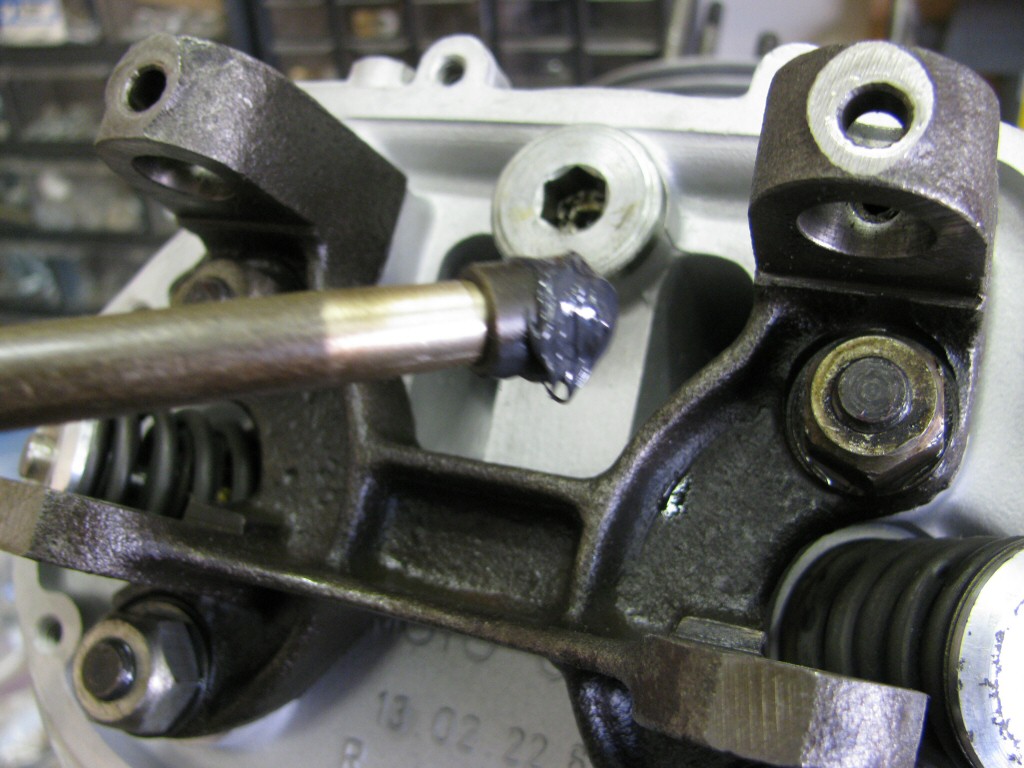

The exhaust valve components in place, ready to torque the bolts that secure the rocker arm in place.

The exhaust valve components in place, ready to torque the bolts that secure the rocker arm in place.Photo courtesy of Gregory Bender.

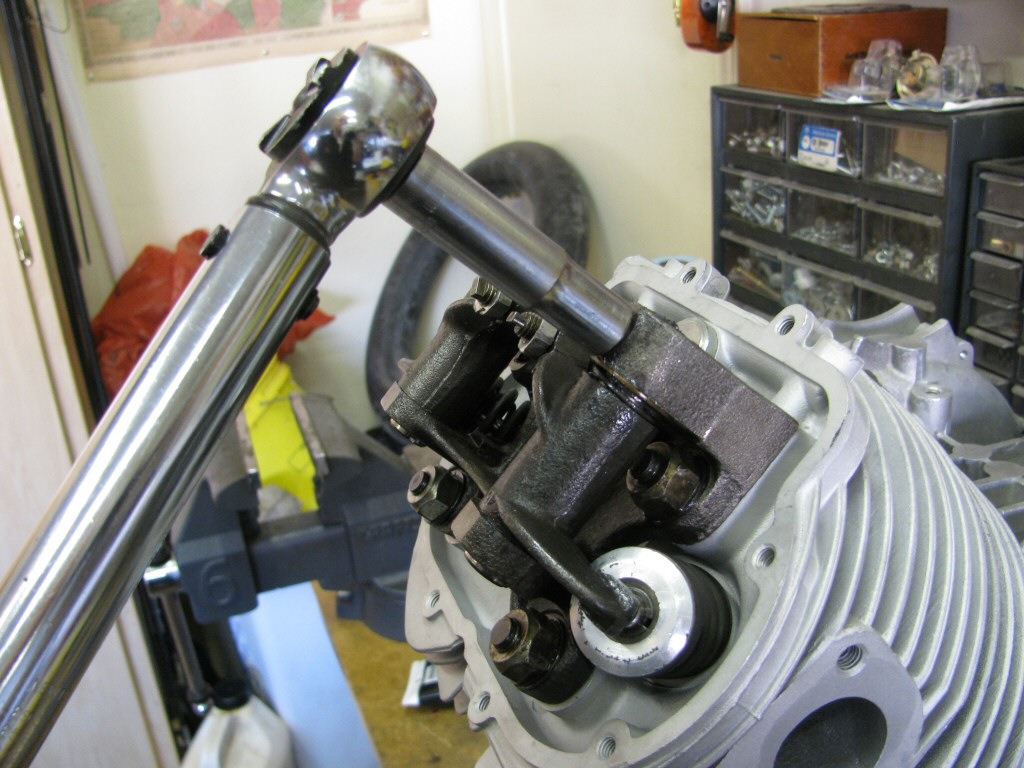

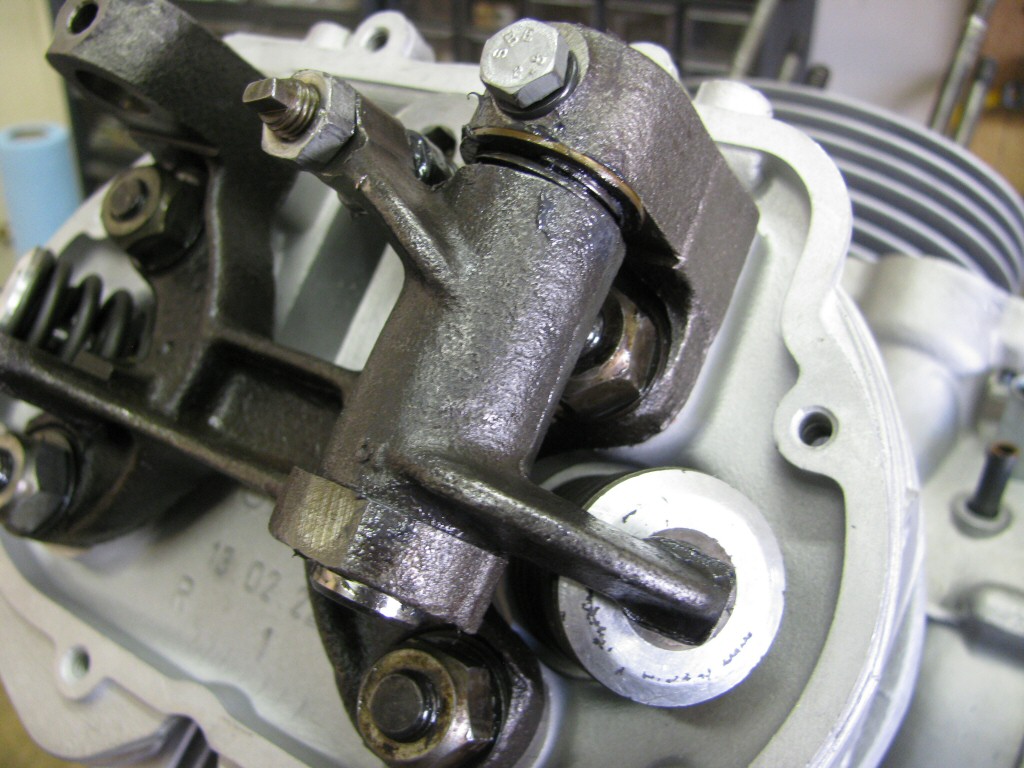

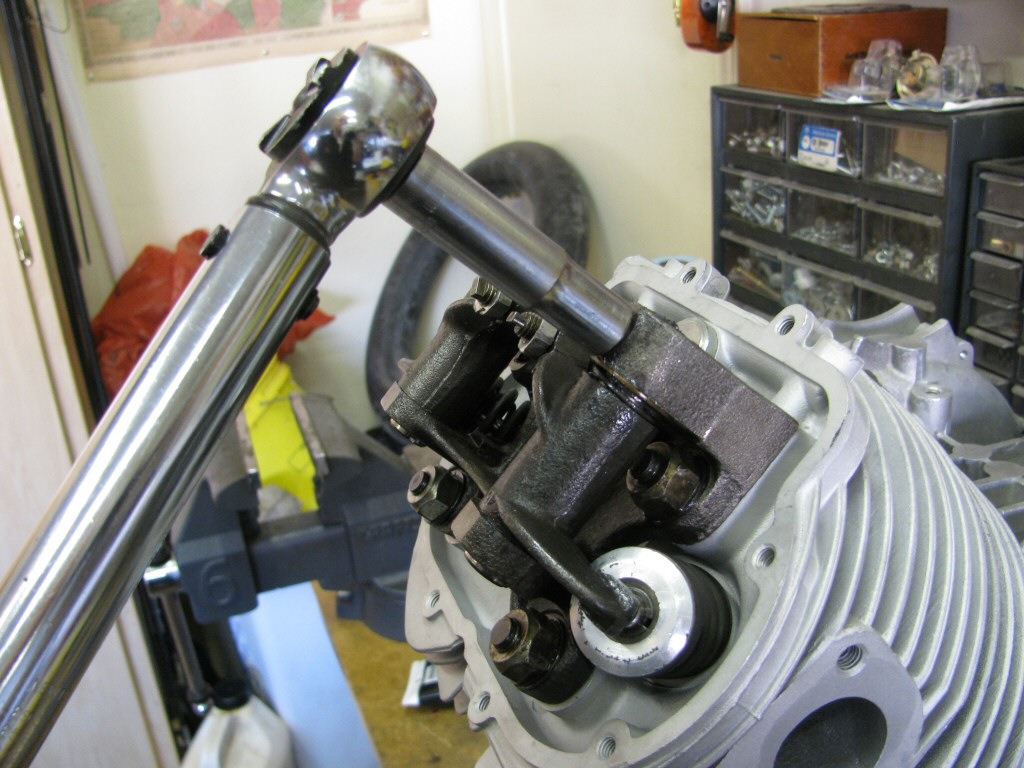

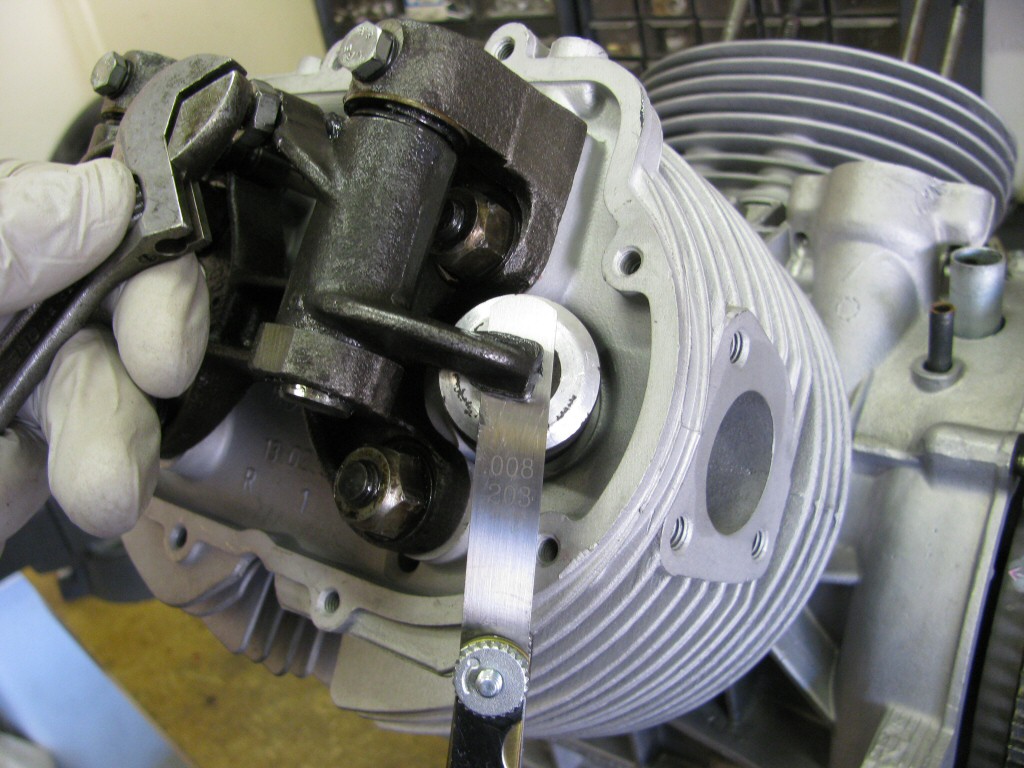

Torqueing the bolts that secure the rocker arm in place.

Torqueing the bolts that secure the rocker arm in place.Photo courtesy of Gregory Bender.

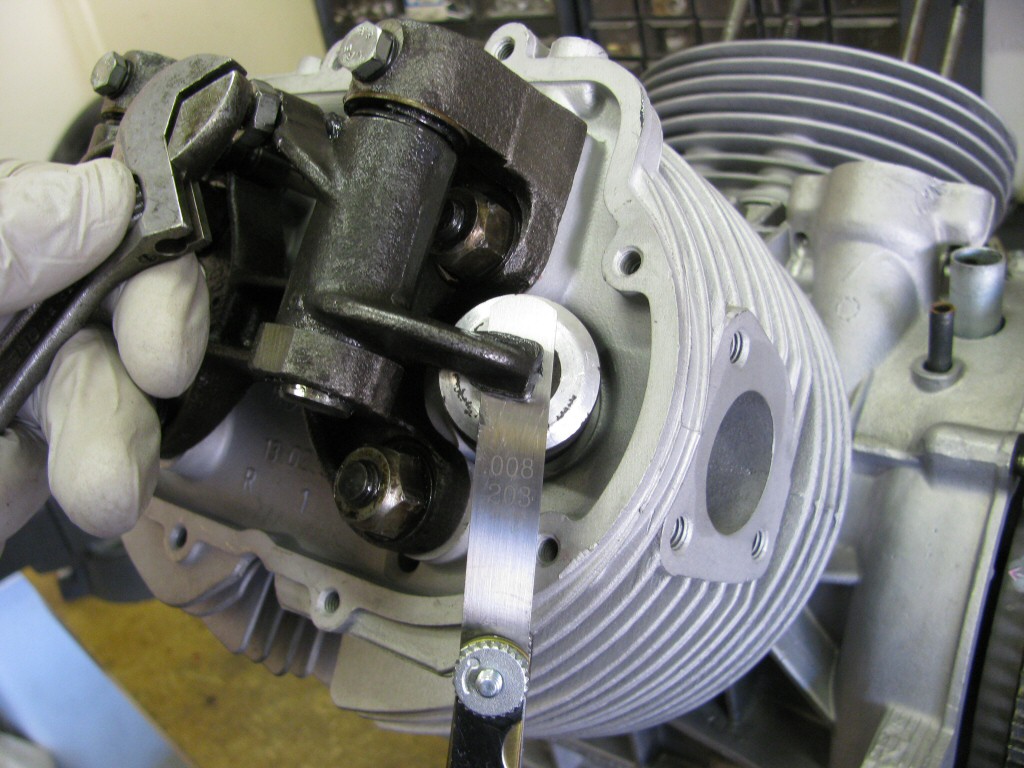

I set the valve clearances per Moto Guzzi specifications.

I set the valve clearances per Moto Guzzi specifications.Photo courtesy of Gregory Bender.

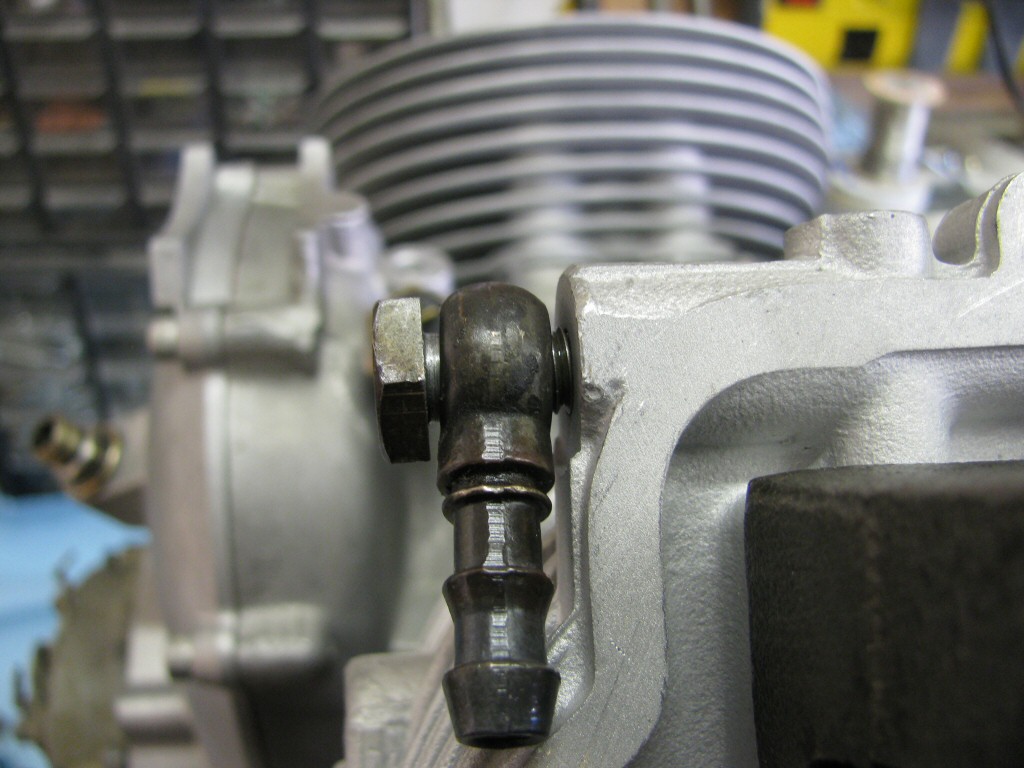

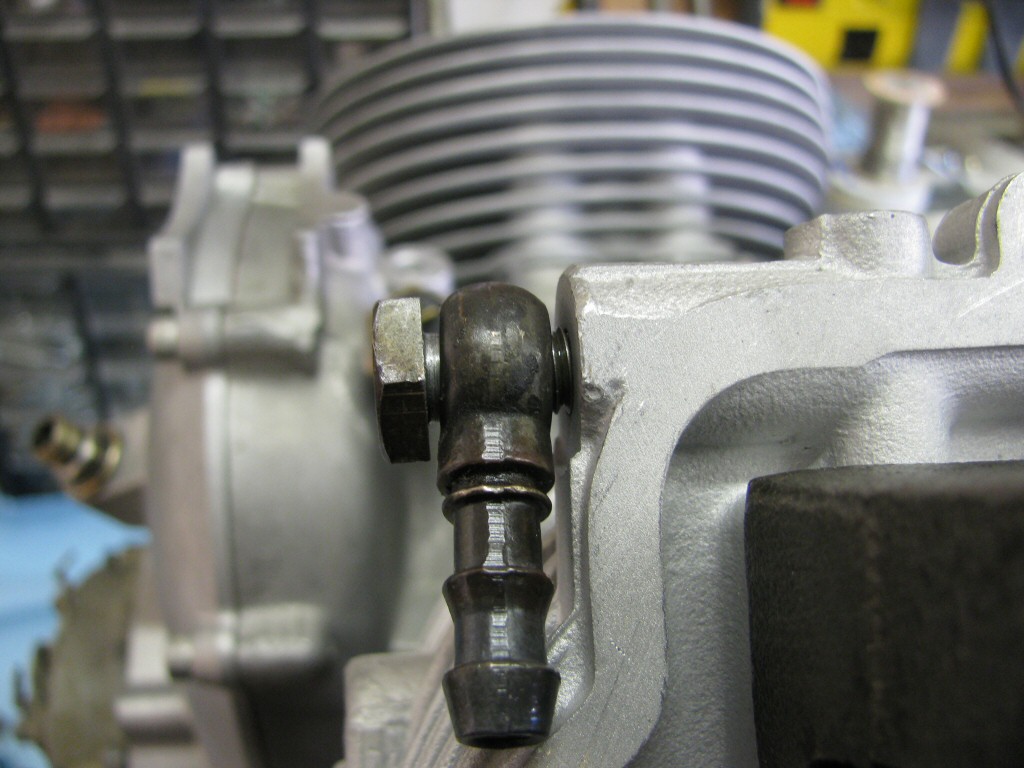

Banjo bolt for the oil feed line loosely fit.

Banjo bolt for the oil feed line loosely fit.Photo courtesy of Gregory Bender.

First entry|Previous entry|Next entry|Last entry