Shift linkage - foot pegs and a 4 speed transmission

Moto Guzzi V700, V7 Special, Ambassador, 850 GT, 850 GT California, Eldorado, and 850 California Police models

Created:

Updated:

Sloppy linkage fixes

The shift linkage on my 4 speed, left side shift transmission was getting very sloppy. With time and use, the clevis pins simply elongate the holes and slop is the result...at least an inch at the shifter in my case.

I've heard of three different fixes:

- Find the next larger size clevis pin (either inch or metric) and drill out the holes to accept this new larger size. It is also recommended that the hole be drilled slightly smaller, then reamed to a precise fit. Thanks to Mark Etheridge of Moto Guzzi Classics and Guy Winton for this tip.

- Purchase bushings and custom fit them to take up the space between the smaller clevis pin and the larger hole. This may also require drilling. Thanks to John Ulrich for this tip.

- Replace the entire setup with Heim joints (also known as ball end joints). I chose this approach because it required the least amount of work and promised the tightest joints over the long-haul. It does, however, yield an appearance that is not stock. Thanks to Ron Komoroski and Rob Prins for this tip.

Here is where I sourced the parts:- Metric 6 mm × 1 mm female Heim joints: McMaster-Carr part number 6275K53.

- Metric 6 mm × 1 mm × 95 mm black-oxide steel stud: McMaster-Carr part number 93275A020. I painted this a dull silver color to help protect against corrosion.

- Bruce Henshaw informed me of another great place to source these parts: Midwest Control Products

- You may also be able to locate these materials through a local semi truck dealer, as apparently many trucks use these joints, too.

Outcome: I have absolutely no slop left in my shift linkage!

Additional notes

I gave up on the shift offset bracket. The clearances were so tight around the shift arm, that I couldn't get the adjustment I needed for the clutch to disengage properly (see photos below). I'm certain that it works great on the Eldo 5 speed...but things are just too tight on the left side of the 4 speed.

Whilst beginning a ride with the local classic owner's group, my shift linkage broke. I had bent the stainless all thread to clear the shift lever. You guessed it, it broke right at the bend. So, I snuck her into 2nd gear and headed for home, grabbed the Quota, and met up with the guys in time for breakfast.

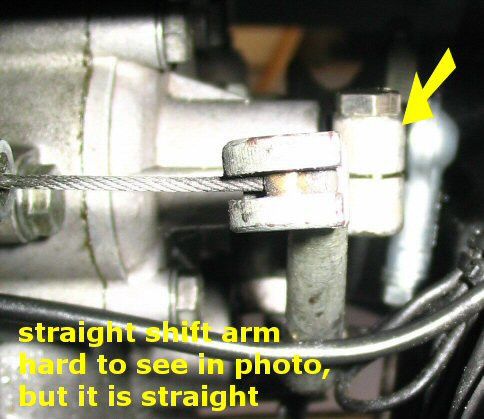

Back home for the fix, I really wanted to continue using my Heim joints and all thread (this time leaving the all thread linkage unbent). So, I scavenged a straight 4 speed shift arm to replace my dog-legged shift arm and found the clearances I needed. These are the little arms that attach directly to the shaft exiting the rear of the transmission (see photos below) - I didn't even know that Guzzi made more than one kind.

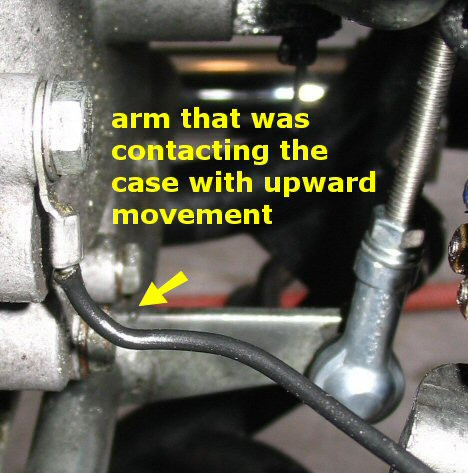

Along the way, I took the time to notice the movement of stock lower shift arm (this is the arm that is welded to the shaft that connects directly to the foot operated shift lever). Low and behold, if the linkage is too short, the lower shift arm will hit a cover bolt on the up-stroke. I made sure this had ample clearance and put everything back together.

From the worn spot on the arm and a contact spot on the case bolt (see photos below) I'm just certain that the extra-bend in the linkage was causing the welded arm to hit the case bolt before it traveled as far as it needed to go...thus shortening my up-stroke and making it difficult to shift.

The end result is that I'm mostly satisfied with my shift linkage. My only improvement now will be to source a proper rod to replace my temporary all thread solution.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Photo courtesy of Gregory Bender.

Gregory Bender's thoughts:

Now that I'm using the 95 mm rod in place of the all thread, I am completely satisfied with my shift linkage. It works properly and has very little play. I love it when a plan comes together!