Cylinder head exhaust nuts - removing stuck nuts

Moto Guzzi V700, V7 Special, Ambassador, 850 GT, 850 GT California, Eldorado, and 850 California Police models

Created:

Updated:

First things first. Use the correct tool to start with before damaging the nut. Do not use pipe wrenches, chain wrenches, hammer and punches, etc. True, you may need to resort to using those tools, but don't start out with them and ruin the nut. A ruined nut will only make the challenge more difficult.

With that disclaimer out of the way, here are the things you can try:

- If you have the option of running the engine up to operating temperature, do so. This will help a great deal. With it very hot, try loosening the nuts. You may need to put a pipe extension on your tool for additional leverage.

- If you cannot run the engine, heat the cylinder head with a MAPP torch or similar. Get it good and hot and then try to loosen the nuts.

- If you can, leave the cylinder head bolted to the engine and the engine in the motorcycle. If you remove the cylinder head, then you will have to figure out a way to hold it in place while you apply force to it. The task is much easier when you have the entire motorcycle to hold everything in place.

- Use liberal amounts of your favorite product designed to loosen stuck fasteners. I am a big fan of using a 50/50 mixture of ATF and acetone.

- Patrick Hayes mentioned the following on the old Yahoo! Loopframe_Guzzi news group (which has now moved to Groups.io):

Where exactly are you heating? The nut and the head are very different metals and react to heat at differential rates. You want the hole in the head to expand but you'd prefer that the nut does not expand. Since they are in intimate contact, that is going to be difficult to modulate.

See if you can keep the flame directly away from the nut itself. Minimize any flame contact with the nut. Once you get it all hot, see if you can channel some cool water on to the headpipe and the nut to shrink the nut.

Do you have a little

buzz

engraver? Could you add some long-term vibration onto the nut to help the capillary action move your solvents into the microscopic spaces between the metals? - Harold mentioned the following on the old Yahoo! Loopframe_Guzzi news group (which has now moved to Groups.io):

If you're taking the jug off anyway, try sitting it a bath of diesel fuel for 2 weeks. I've freed up stuck cylinders that I didn't think would ever move again.

- Kevin Faison mentioned the following on the old Yahoo! Loopframe_Guzzi news group (which has now moved to Groups.io):

Here is how I got the frozen exhaust nut out of my head after giving up on heat, penetrating oil, etc,

- Saw off the head pipe close to the exhaust nut.

- Chisel out the remaining piece of steel header pipe to expose just the exhaust which I believe is made from brass if I remember correctly. I used a small craftsman chisel and hammer to collapse the exhaust tube enough so that I could then cut through it along its remaining length (or along the same direction as the exhaust flow).

- I then used an end mill mounted in a drill to grind a groove in the brass nut along its length. I did not cut the grove deep enough to hit the threads in the head. I only removed enough material so as to weaken the nut enough so I could collapse it with a hammer and chisel like I did with the exhaust tube. Collapsing the exhaust nut even a little pulls the nut away from the threads and before you know it you will have that nut out.

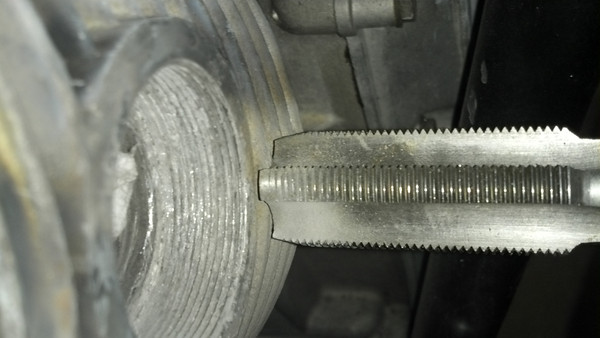

Here is a picture of the end mill in the drill. Photo courtesy of Kevin Faison.

Here is a picture of the partially collapsed exhaust nut after I removed it from the head. Photo courtesy of Kevin Faison.

The threads in the head were packed with corrosion and that was why it would not budge. I could see there was no way I was ever going to get that nut to turn with all that corrosion in there.

To remove the corrosion I used a hand held metric tap with the correct pitch to dig out the corrosion. I took my time and just worked the tap around until all the corrosion was removed. The threads were found to be in good shape once cleaned out.

Here is a photo of the tap operation. Photo courtesy of Kevin Faison.